S3 - SLUDGE DRYING SYSTEMS

Our drying systems may be used for dewatering, drying and hygienisation of sewage sludge, biosolids, bio digestate or other substrates. With our technology we are able to handle substrates with dry matters down to 0,03%.

Reference - Salten Havbrukspark AS

The purpose of this project is to adapt existing technology from sewage, pig faeces and ligning in order to treat fish faeces.

Installation during Q3 - 2018.

HEAT RECOVERY

Our plate heat-exchanger is designed for the recovery of thermal energy from any type of gas. Our new innovative lammelae will revolutionize the heating industry. It enhances the overall energy efficiency of heating processes while substantially reducing the operating costs of the entire system. The lammelae is alloyed as semi-conductors.

Reference -The Derome Group

The Derome Group is one of Sweden’s largest family-owned lumber industries dating back to 1946.

A total of seven plate heat-exchangers since 2010. Note that the outlet tube, inlet tube and the gabels har insulated.

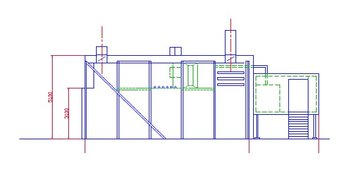

HIGH TEMPERATURE DRYERS

We offer both progressive dryers and chamber dryers suitable for sawed timber, waste, sludge from human, pigs and fish drying at high temperatures.- t;dry/t;wet = 1000 C/1000 C

Data

LS Optics has data, dry/wet temperatures to dry different substances to required moisture content - or dry matter.

Our heat exchangers and also the heat exchangers in our timber dryers are made in stainless steel and are alloyed so that we are creating heat with wavelengths where moisture has its highest energy absorption coefficient.

The dryer has two timber wagons. The first one is in the dryer and the second one is being prepared for the next drying session.

The dryer is designed as a walk-through dryer with only two rows of blow depths to reach an low moisture gradient with the confidence interval 1. This means that 95% of the peaces are +- 1%.

The drying temperature is 1080 C / 990 C.

The drying is done in saturated steam to avoid cracking.

Example: White pine 47 mm - Drying time:18-20 h incl. 4 h moisture equalization and 0,5 h downcooling with air to a final moisture content of 12%.

All our dryers are insulated with FOAMGLAS®.

Walls and roof: FOAMGLAS® T3+ 400mm insulation - Read more

Floor: FOAMGLAS® HLB 1600 360 mm insulation - Read more